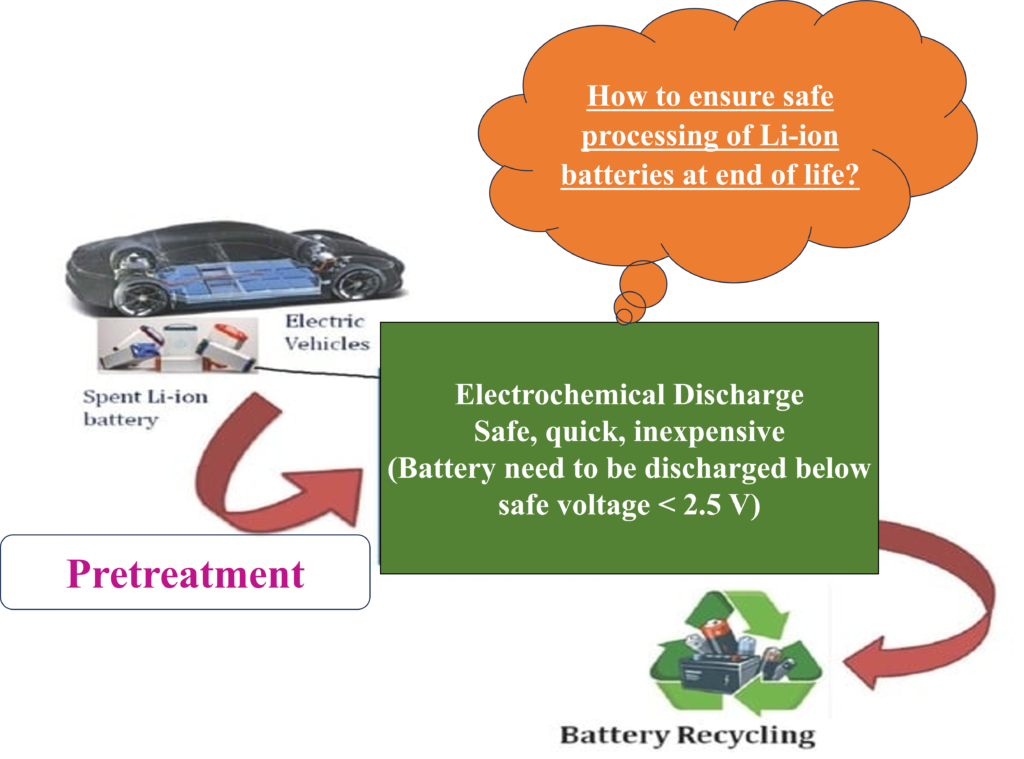

How to ensure safe processing of Li-ion batteries at the end of life?

Neha Garg

Aalto University, Finland

LIBs that have reached the end of life and are sent for recycling, may still hold some residual energy, that is dangerous during handling and processing. The high voltage and reactive components of end-of-life LIBs pose safety hazards during mechanical processing and crushing stages, as well as during storage and transportation. Electrochemical discharge method provides an efficient, quick, and inexpensive way to eliminate such hazards. For the first time, we are demonstrating a possibility to use inorganic redox couple for efficient electrochemical deep discharge of LIBs up to below 0 % State of charge (SOC) which is low enough for safe battery handling and less corrosive in recycling centers. While comparing three batteries from different manufacturer: we have observed that battery which contains high Ni-content stainless steels are more suited for an electrochemical discharge in aqueous environment, such batteries discharged more efficiently and after rebound remains below 2.5 V.